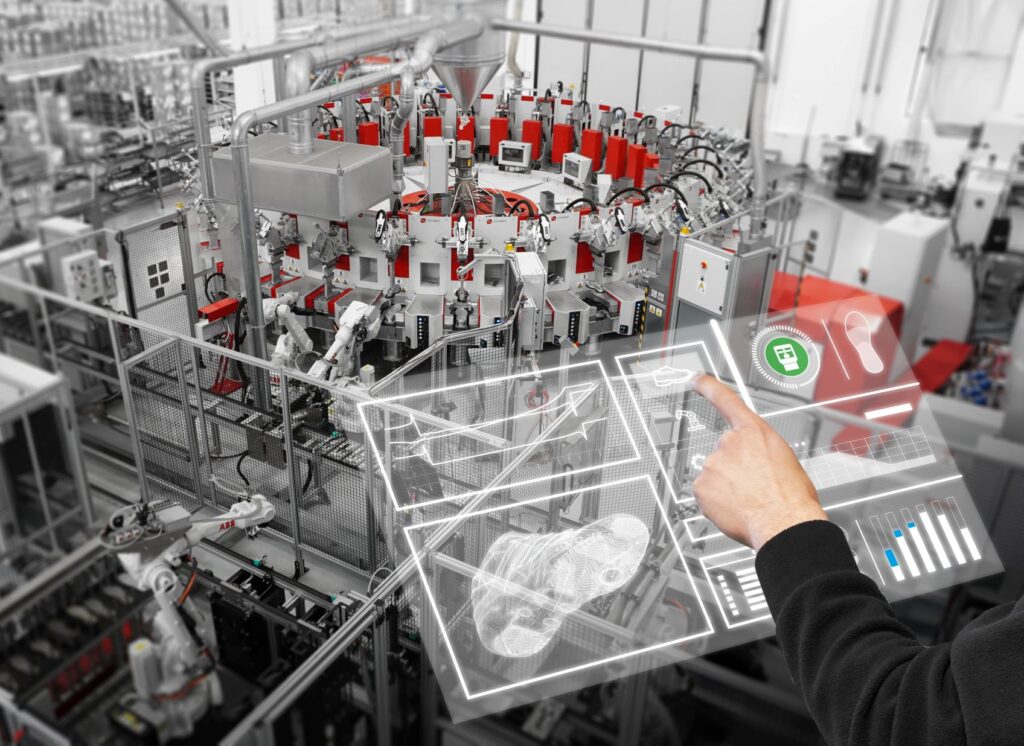

Establishing a new man-machine relationship that improves and simplifies work; managing products that are very different from each other by category and design; offering high performance and advantages in terms of quality and production efficiency. These are the concepts behind PRO-TRAC, the automatic line for the footwear production developed by STEMMA..

PRO-TRAC is the last management and handling system that integrates the rotary sole molding machine with the robotic stations for the upper processing. All process information and specifications of each product are shared in a “cloud database” between the different work units of this advanced production plant. The required processes are performed automatically on specific products, identified by RFID technology at the entrance to each station.

The reduced skilled workforce is entrusted with the control and management activities and a few critical operations which, on the other hand, thanks to the use of plastic lasts and automatic shoe lasting and delasting operations, are made easier and more ergonomic and improved in terms of quality and yield.

Thanks to the best balance of the production cycle and to the zeroing of downtime between the different working steps, the system guarantees the injection machine to unceasingly run, thus bringing productivity to the highest efficiency levels.